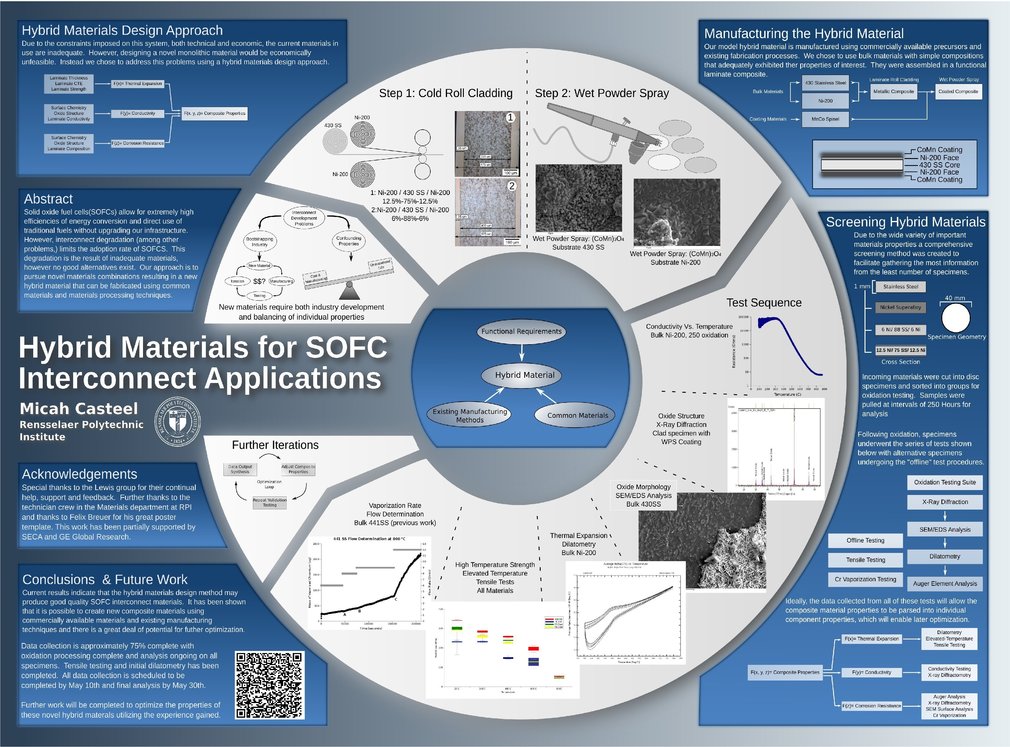

Developing Hybrid Metallic Materials for Solid Oxide Fuel Cell Interconnect Applications

The worlds energy landscape is rapidly evolving from hunter-gatherer approach to an agricultural approach where we can “grow our own” energy. This provides a fantastic opportunity to increase the sustainability of our manufacturing, the efficiency of our homes, and many other advances. This revolution is built on a confluence of diverse energy production and efficiency boosting technologies, both traditional and novel. An important aspect of this process is increasing the efficiency with which we convert between one form of energy to another. Historically, the most common method of converting chemical energy consisted of burning it, often inefficiently, and with toxic effluent. Fuel cells offer a new way to convert chemical energy, found in traditional hydrocarbons and novel biofuels, at high efficiencies. Solid oxide fuel cells(SOFCs) in particular allow for extremely high efficiencies of energy conversion and even allow direct use of traditional fuels without upgrading our infrastructure. However, there are still challenges to bringing SOFCs to the market at economical prices. One of these problems is interconnect degradation, which results in performance losses and premature failure. This degradation is the result of inadequate materials, however no good alternatives exist, and pursuing advanced materials results in an overly expensive device. Our approach is to pursue novel materials combinations resulting in a new hybrid material that can be fabricated using common materials and materials processing techniques. Ideally this new material will exhibit superior materials properties at a significantly lower price point than alternative advanced materials solutions.

Judges and Presenters may log in to read queries and replies.