Very cool research! The video was a great explanation for audiences at any level. Best of luck!

-

-

Thanks Samantha!

-

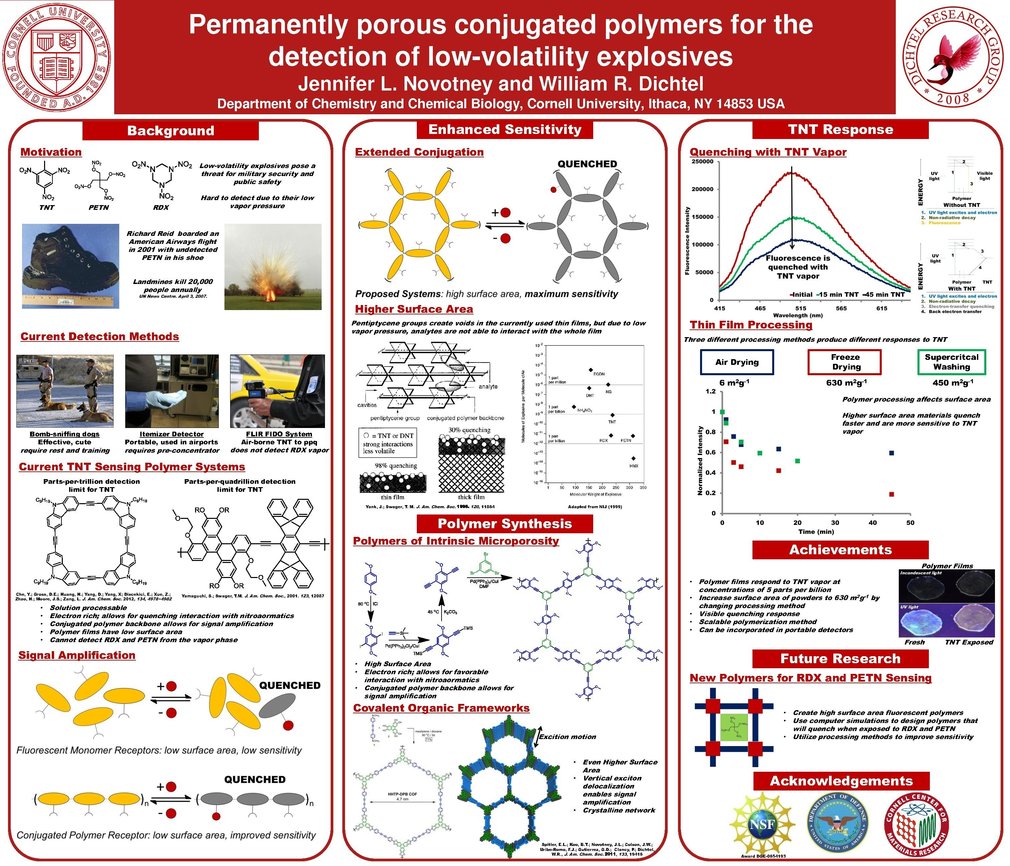

You did a really good job explaining your research to a general audience – very interesting!. How scalable is the polymerization method (and how easy is it to grow the films to get the 5ppb response you need?)

-

The polymerization seems to be very scalable (at least within a laboratory setting). Once I found the right polymerization method I have been able to consistently get responsive films.

-

Nice work! Perhaps I missed it, and just out of curiosity, what concentration of TNT would be considered the minimum level at which people interested in implementing your polymer would need to detect? In other words, what is the minimum amount of TNT that would raise safety concerns, and what are hoping to achieve for your lower limit of detection?

-

Amber, that is a great question. At ambient conditions the concentration of TNT vapor near solid TNT is 5 parts per billion which is the concentration I have been testing. So this means my polymer can detect TNT in a real world setting. Being able to detect at lower concentrations would be nice though.

-

Nice work, especially if it can save lives by detecting explosives.

What are the real world uses for this though? Can a device be made to monitor your polymer, so if it goes dark, the device would alert? Some sort of box with a intake vent, sucking in air with an internal fan. Then blowing that air over your polymer, a monitor checking to see if it goes “dark”, and when it does – Alerts that an explosive has been detected nearby. Of course the polymer part would have to be in a cartridge or something like that – so you can just reinsert a new one from time to time.

I can envision something like that being used at airports, on airplanes, even on the front of military vehicles – to test the air for IEDs. Good luck with your research!!

-

Further posting is closed as the event has ended.

Judges and Presenters may log in to read queries and replies.