I received a question, so I am posting my reply here in case other people have the same question.- - - - - - - -

Hi Tristan,

this is fascinating work. What are its implications? Where do you think this will be most important?

Thanks- - - - - - - -

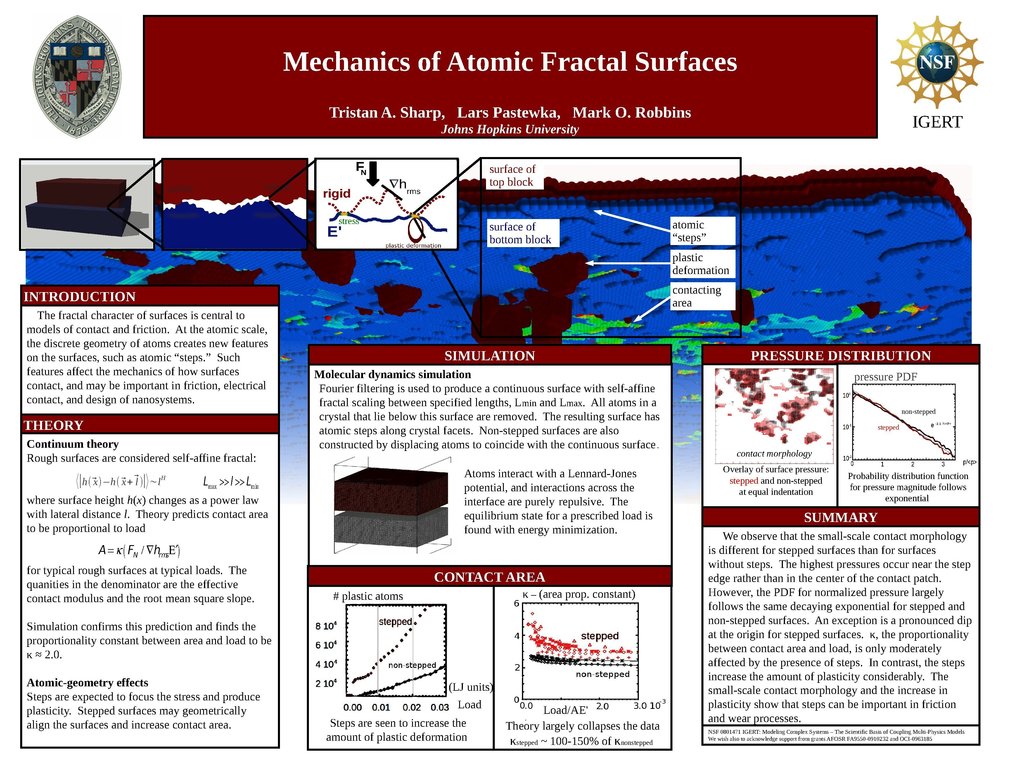

Thanks! We think so too. If we understand how the surface geometry of solids can change contact properties, then we’ll be closer to understanding friction, wear, adhesion and several other fundamental processes that engineers mostly treat phenomenologically right now. What’s more, this all becomes critical when designing nano-scale machines, where these processes dominate. These results presented here are a piece of the puzzle. Hopefully this work will contribute to the dialog as we try to discover what’s important in engineering at the atomic-scale. Atomic-scale engineering, of course, promises great advances in medicine, energy, communications, etc.

Another way to put the results succinctly is the following: We see evidence that there is little need to incorporate “steps” into the theory of rough contact if the only quantity of interest is contact area. (A researcher trying to interpret thermal conductivity data may wonder if the sample’s stepped surface affects the amount of area touching.) However, the steps produce stresses that are not predicted in step-less theories, and so therefore steps may be necessary in a more accurate theory of wear, for example. (An engineer designing a submicron mechanical device may wonder if a material without surface steps is necessary to diminish wear.)

Hope this answers your question.

Judges and Presenters may log in to read queries and replies.